DK Company is a clothing company based in Ikast, Denmark, with two additional divisions in Vejle and Copenhagen. Founded in 2001, DK Company has, with 2,400 employees and 450 retail stores, grown to become one of Europe’s leading suppliers of fashion.

Sometimes, you run a proof of concept (PoC) that’s so successful, you just have to turn it into a full-blown case study. Which is what happened when we partnered up with Danish multi-brand fashion group, DK Company, and implemented our data-driven supply chain recommendations inside a representative subset out of their 250+ locations.

Within the timespan of no more than 5 weeks, the PoC we did for DK Company led to some staggering results. In this case study, we’ll show you what challenges DK Company were facing, how we solved these challenges for them, and how this helped maximise their Return on Inventory.

To kick things off, let’s take a closer look at DK Company and some its main business characteristics:

This should give you a better idea and understanding of the type of businesses that can really benefit from Wair’s software and services, although we can already create great results for retailers starting at $50m revenue.

When we first got in touch with DK Company, they were going through a process of digital transformation, as their competitors were growing at a faster rate than they were. Some of the challenges they were facing included:

Solving these types of challenges is exactly what Wair’s data-driven supply chain solutions specialise in. And to start off, we ran our standard PoC to scientifically prove a positive impact with minimal risk.

After the onboarding, we set up a Proof of Concept (PoC). This phase involved selecting the most representative stores and dividing them into test and control stores.

Test stores will run according to our data-driven supply chain recommendations, whereas control stores keep running business as usual.

We spoke to Thomas Fjord Pedersen, IT Planning Manager at DK Company, responsible for all ‘merchandise planning’-related systems about the collaboration and the onboarding process. Thomas: “We had worked with a setup for re-ordering in our ERP system before.”

This turned out to be a very cumbersome and manual process. It wasn’t actively adjusting the target stock, for instance. “We quickly learned about Wair’s advantages, and decided to aim on fully turning it into our new robot for re-ordering.”

The 5 week onboarding and implementation process was also very much appreciated by the DK Company team.

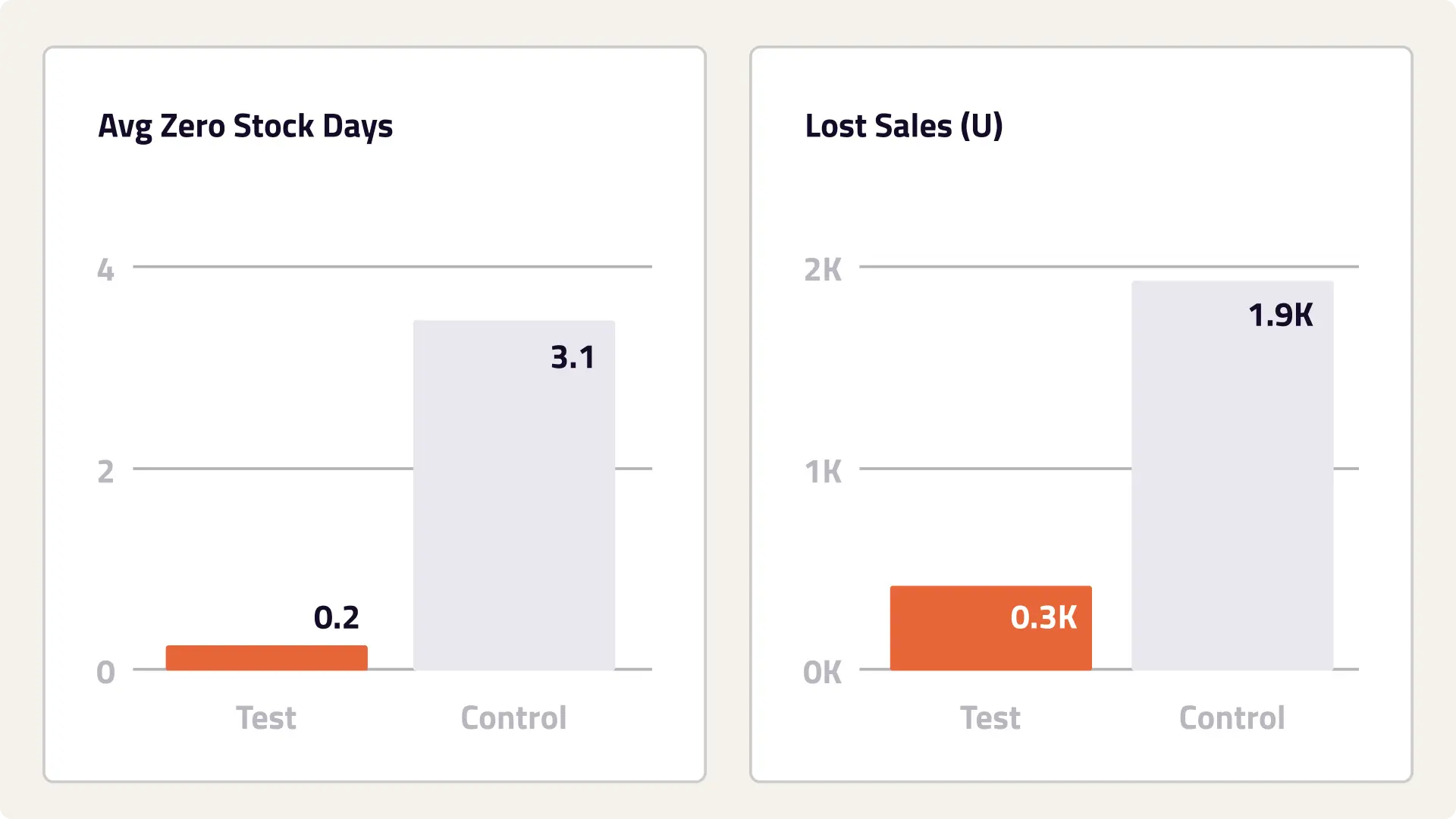

Here , you can see the results achieved by the DK Company stores involved in the PoC phase. This analysis is a snapshot of the results, 3 months after going live.

First of all, the number of stockouts were reduced to a fraction of previous levels, significantly increasing the opportunity to convert merchandise to cash.

Lost sales in test stores also decreased by more than 84% because the right products were available at the right time, all the time.

Sales per SKU increased by more than 38% in only 3 months due to a better product flow to where consumers come to buy. DK now sells 66% more in the test stores than in control stores.

And, lastly, in this initial phase, the sell-through rate per SKU also increased, without having to remove redundant inventory.

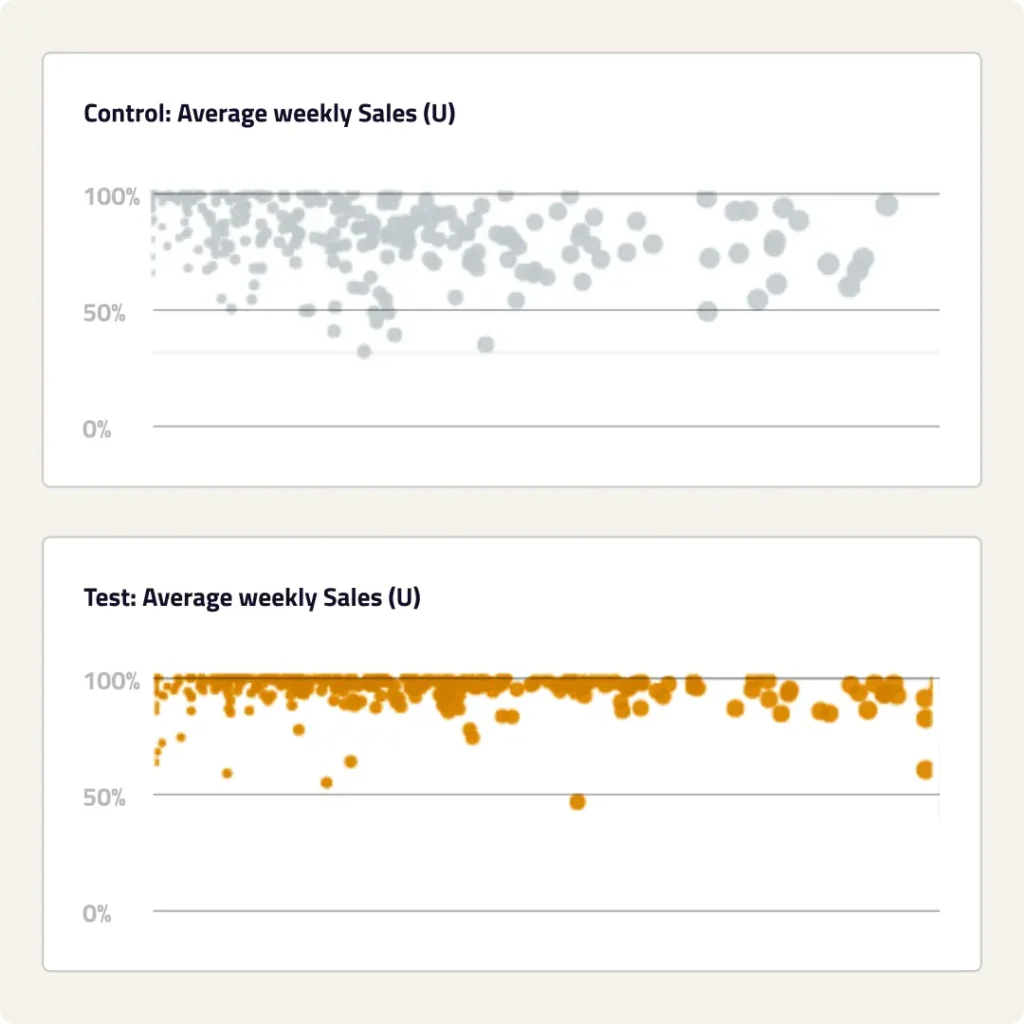

Apart from specific individual metrics improving, DK Company also experienced an overall improvement of its products in test stores. If we are to line up the differences between the control and test stores, we find the following.

In the control stores, products have:

In test stores, products have:

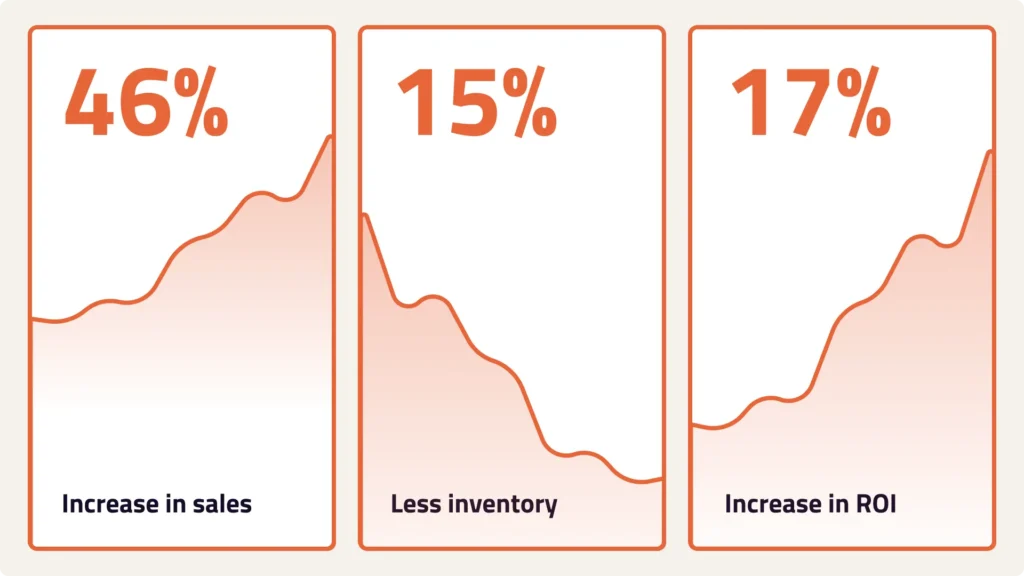

By adopting a responsive supply chain DK Company has achieved a significant sales increase with less inventory. This translates into an increase in Return On Inventory and overall business profitability.

By implementing Wair’s data-driven supply chain solution, DK Company was able to reduce stock and improve products’ availability, which in turn led to:

Wair will continue helping DK Company increase their market share and outperform its competitors.

At Wair, we make consultative recommendations to help you shorten lead times, increase throughput and maximise Return On Inventory.

“When supply and demand are not in sync, supply chains generate waste, known as discounts and lost sales. The potential for margin improvement is huge when the shelf responds to real demand. It is our goal to capture that potential and improve your Return on Inventory.” – Jasper Zeelenberg